YAMAHA's

casting & forging technologies

improves cost-efficiency and weight reduction

-

EV-related

Components -

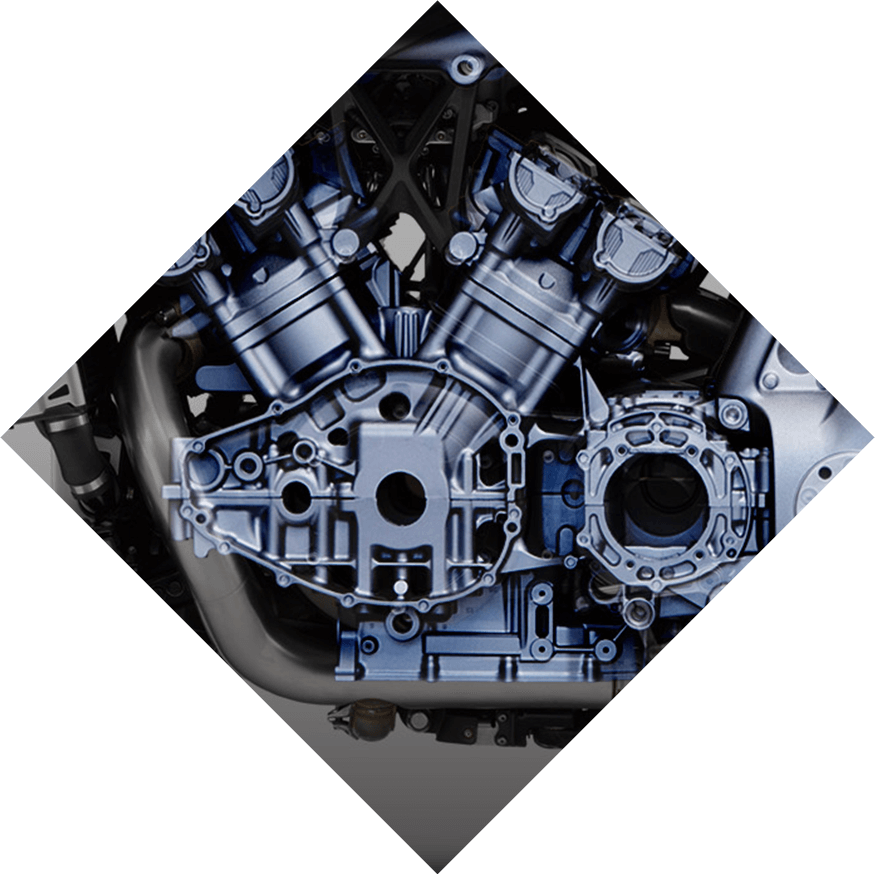

Transportation

Equipment -

Telecom-related

Equipment

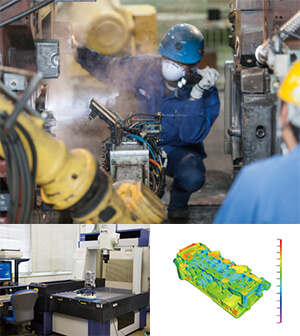

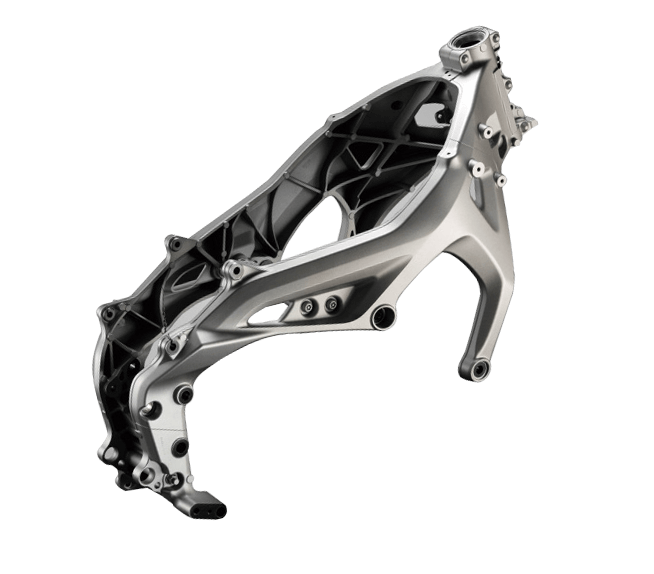

Yamaha Motor's casting is ideal for parts requiring reductions in weight and component numbers.

Benefits Based on

Real-world Examples

-

: Integration

The number of the components reduced from 120 to 2, and a roughly 98% reduction of components count.

-

: Weight Reduction

We have achieved 30% weight reductions.

What you can achieve

with Yamaha

- Mass-production of large, thin-walled parts

- Reduced weight

- Fewer components needed

- Lower manufacturing costs

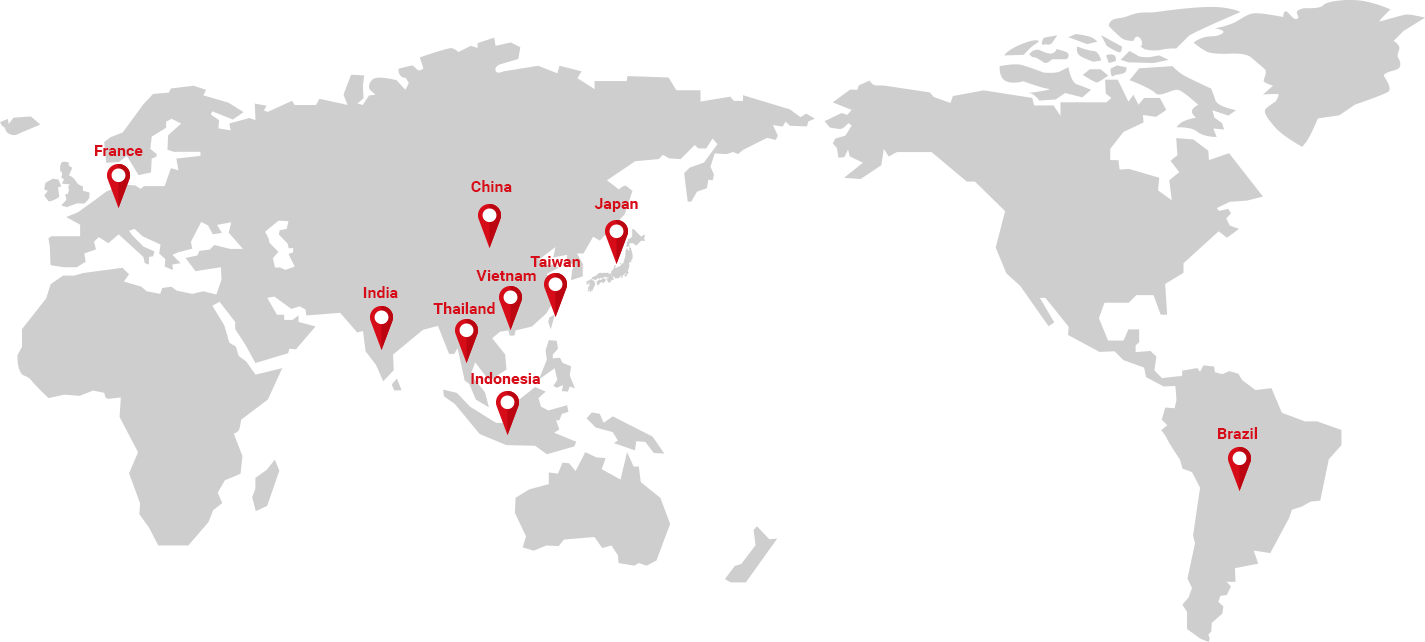

- Casting

-

-

Controlled Filling(CF) Die-Casting

Reduces weight by about 30% and roughly 90% reduction in the number of components needed for a part. Its use can typically reduce manufacturing costs by about 20%.

-

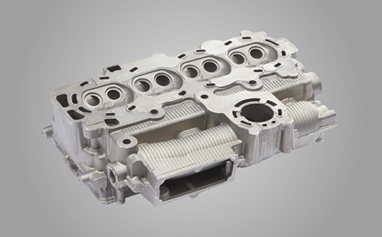

Cylinder Heads

One-piece cylinder head greatly contributes to a more compact and less costly engine.

-

- Forging

-

-

Forged Aluminum Pistons

Selection criteria for raw materials, special manufacturing methods and improved die and mold durability - all this leads to success in producing forged aluminum pistons at a much lower cost.

-

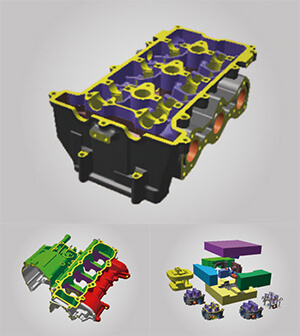

Why we can do what we do

At Yamaha Motor, we use concurrent engineering based on 3D data to create the products that our clients desire with efficiency, speed, and the most optimal shape and construction. We can guarantee product development that integrates the three essential elements of quality, cost-effectiveness and delivery time.

Integrated Streamlined Manufacturing

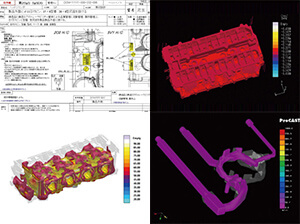

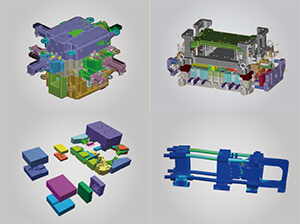

Global Manufacturing Network

Offering “Made in Japan” Quality in Countries Around the World

The Yamaha Motor Group has established manufacturing locations in countries around the world, primarily in the ASEAN region. Each of our factories adopts flexible production layouts, and operates casting machines to global standards. By using the same molds, dies, manufacturing methods and materials, we are able to manufacture high-quality cast parts and products to the exact same standards in any of these countries.

Overall Production Capacity of Yamaha Motor Group

-

High-pressure

die-casting machines216 units -

Low-pressure

casting machines93 units -

Gravity casting

machines38 units -

Shipments

Aluminum 11,160 tons/month -

Shipments

Cast iron 1,370 tons/month

Message from

our Metal Experts

Offering “Made in Japan” Quality in Countries Around the World

-

Yukihiro Enomoto

Engine manufacturing Section

Even if it's an item other companies couldn't create, if you bring it to us, we'll make exactly what you're looking for.

-

Atsushi Suzuki

Casting Chief YMC

If it's a tough challenge, I believe it's our style to rise to meet it head on.

-

Tomoshige Okude

Unit Engineering Division

Because we've always had to meet the differing demands of our various productss, we're always developing new technologies.

We accept inquiries regarding casting at any time.

Please feel free to contact or consult us for any questions or requests you may have.